2-axle 3-way tipper trailer - building site

- Tipper body construction using conical, trapezoidal profile side members in high-strength, lightweight design with small bottom panels for high dent resistance and shock absorption

- Insulated hollow chamber body for slow cooling, freezing and adhesion of load

- Hard chrome-plated, high-quality tilt cylinder

- Installation of axles from well-known manufacturers such as SAF or BPW

- OPTIONAL: Pull-out drawbar, max. 600 mm adjustment, with Getofix drawbar support

- OPTIONAL: Bordmatic (= hydraulically folding side wall) on left side

- OPTIONAL: Reinforced side walls with material-repellent membrane construction made from fine-grained special steel panels

- OPTIONAL: Electropneum. side wall pendulum locking with switch operation in cab

- OPTIONAL: Aluminium flap on lateral central locking shaft

- OPTIONAL: Standing platform comprising aluminium safety grid with guardrail and step unit

- OPTIONAL: Foldable lashing rings

2-AXLE 3-WAY TIPPER TRAILER - BUILDING SITE

For handling bulk materials such as sand, gravel, rubble, ground excavation etc. on building sites

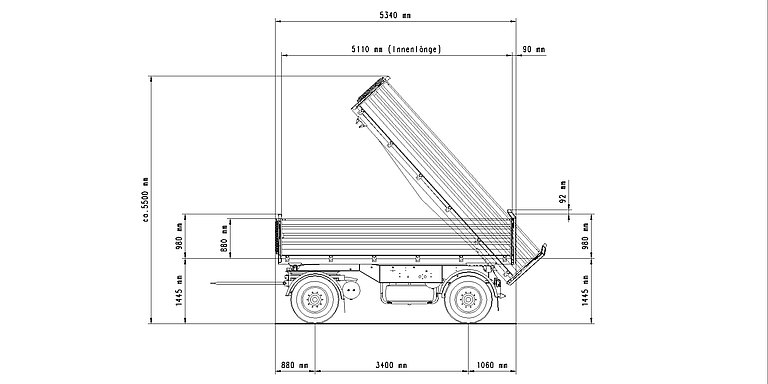

Internal length: approx. 5,100 mm

Internal width: approx. 2,420 mm

Total width: 2,550 mm

Loading height, unladen: approx. 1,450 mm

Naxtra welded steel frame construction

Connector lock for tipper body with cross-over protection

Air suspension with autom. lowering device via inductive switch

Drum brake axles, S-cam brake 420/180 mm, autom. brake linkage adjuster

each with 9 t axle load

Tyres :

4 x 385/65 R 22.5 160J, manufacturer as per factory specifications

4 steel wheel rims 11.75 x 22.5, 10-hole, without rim offset , silver

Brake system according to EC Directive 71/320 or ECE R13

Two-line brake

Spring-loaded parking brake on 2nd axle

EBS - electronic brake system

Wabco 4S3M = both axles sensed

RSS - stability program

Steel air tank

1 tipper cylinder for 3-way tipping, approx. 30 t initial lifting force,

1 arrester cable

1-pipe system with hydraulic connecting hose incl.

plug-in coupling NW13, without truck attachments

24 V lighting system according to EC Directive 76/756/EWG

2 seven-chamber tail lights

LED side marker lights

2 clearance lamps

2 contour lights

Fixed cable(s) with 2 x 7-pin or 1 x 15-pin connector

Blasted with steel granulate, treated with zinc dust primer and spray painted with 2-component acrylic paints for commercial vehicles (standard RAL or truck colour)

Plastic and hot-dip galvanised parts unpainted,

powder-coated attachments/installation parts black

Reflective contour marking strips across entire length of sides and all-round contour marking at rear (white on sides and red at rear by default), according to ECE 48

Wheel chock(s) as per regulations

Noise dampers

Fixed aluminium trapezoidal underride protection, unpainted

Single wheel plastic mudguards with spray protection as per regulations

1 spare wheel bracket for 1 spare wheel

Side impact protection made from aluminium profiles as per regulations, coated black

Hooks for dosing chains on swivelling rear wall

Gross weight (techn.): 18 t

Payload: approx. 13 - 14 t

Tare weight: approx. 4. 3 t

Full-steel welded construction with fine-grained special steel floor panels, 5 mm

(slight floor unevenness possible due to weld distortion)

Fixed steel plate front wall, 4 mm, approx. 980 mm high

1-part reinforced aluminium hollow profile side walls, 60/40 mm, approx. 880 mm high, foldable with extended swivel bolt locks and spring lifting aid, hinged with man. central locking

4 mm steel sheet rear wall, approx. 980 mm high, hinged with raised bearing and autom. pneumatic locking

Rear markings as per ECE standards

2 fixed rear corner posts, raised, side-mounted

Fixed drawbar , 40 mm drawbar eye , with silent bushing and drawbar locking device

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.