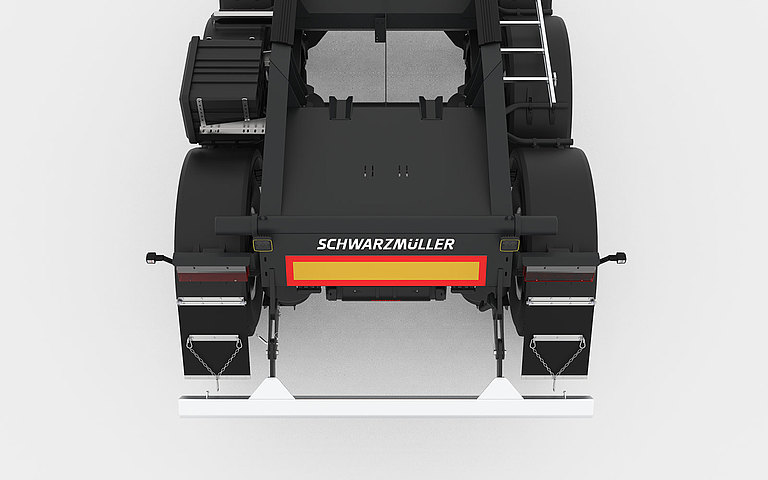

3-axle-aluminium-box-body-tipper-semitrailer

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/b/csm_sm-kipp-fahrzeuge-kippsattel-3-achs-aluminium--kippsattelanhaenger_f83ae111bc.jpg)

- Stable and torsionally rigid steel chassis design with extra torsion shafts for a significant payload advantage

- Automatic lowering device for maximum stability

- Hard chrome-plated, high-quality front tilt cylinder

- Slanting front wall for optimised load distribution

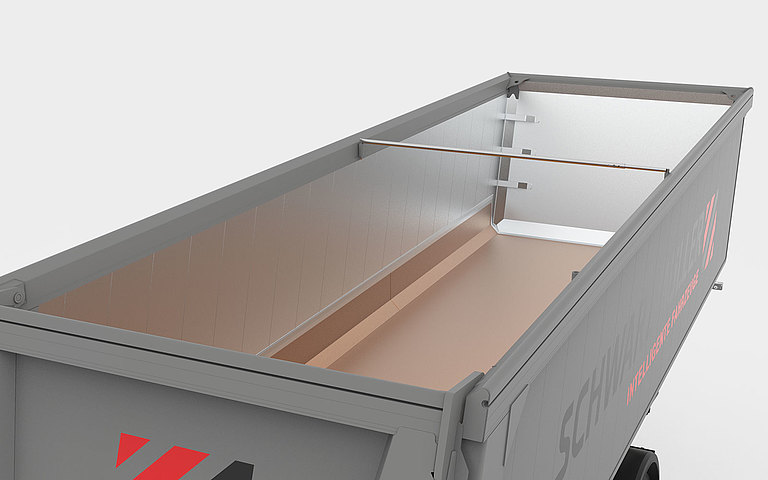

- High-quality, hollow profile aluminium body for high resistance to impact and wear

- Standing platform at front wall for operating the roller tarpaulin

- Axles from well-known manufacturers such as SAF or BPW

- OPTIONAL: Removable grain feeder with dosing lever and discharge funnel in pendulum rear wall

- OPTIONAL: Body sizes available for different cargo volumes

- OPTIONAL: Unscrewed wear plate

- OPTIONAL: Quicksilver® plastic wear plate for perfect sliding of transport goods

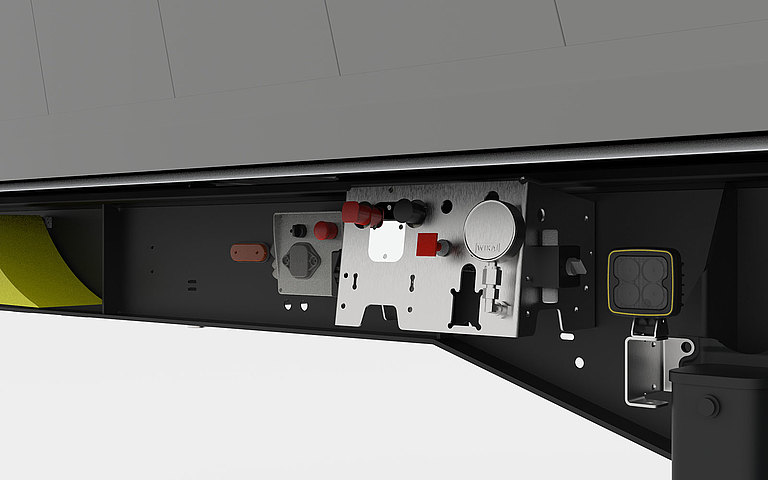

- OPTIONAL: SmartBoard for reading data via the display on the vehicle (mileage, axle assembly load, brake diagnostics, etc.)

3-AXLE ALUMINIUM BOX BODY TIPPER SEMITRAILER

for road use for sand, crushed stone, digging, etc.

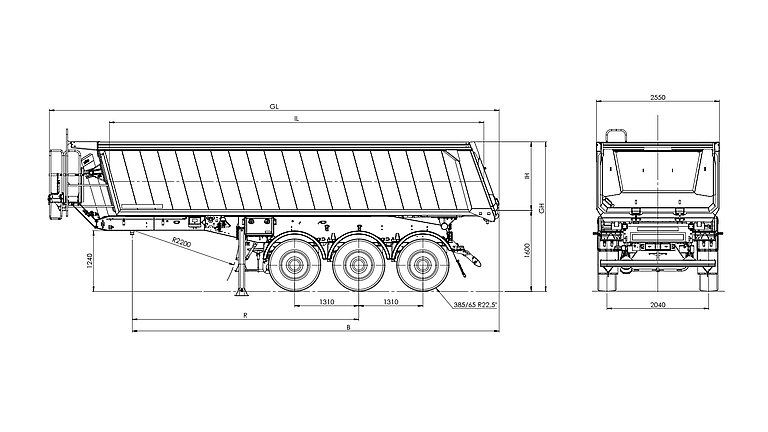

Approx. body inside length 7,350 mm

Approx. body inside width 2,340 mm

Approx. body inside height 1,400 mm

= Approx. cargo volume 24 m³

Total width 2,550 mm

Approx. loading height when empty 415 mm above the fifth wheel coupling

Welded steel frame design in weight-optimised lightweight design

Replaceable 2" kingpin

Air suspension with automatic lowering device operated by inductive switch and lowering lock operated by rotary switch on semitrailer

Air suspension unit with low-maintenance disc brake axles, ø 430 mm,

3 x 9 t rigid, wheelbase 2 x 1,310 mm

Automatically lifting front axle = lifting and lowering depending on the weight and together with forced lowering incl. speed-limited starting aid for pushbutton operation in the driver's cab (without pushbutton installation on our part)

TYRES

6x 385/65 R 22.5 160J, prod. according to factory selection

6 steel rims 11.75 x 22.5, 10-hole, offset 120 mm, silver

2 height-adjustable steel folding jacks (only detachable when empty)

Brake system pursuant to EC Directives 71/320 and/or ECE R13

Two-wire brake

Spring-loaded parking brake on 2 axles

EBS - electronic braking system

Wabco 2S2M = one axle sensed

RSS - stability programme

Aluminium air tank

1 high-pressure front cylinder for backward tipping, tipping angle approx. 49°

1-tube system with fixed screw coupling HDK BG6 coupling thread M48x3

Aluminium hollow profile body with upper stabilising frame;

Reinforced front wall,

Side walls from hollow profiles 40 mm, smooth inside and outside,

Slanting front and rear wall in side wall height = circumferentially flush

Hard aluminium inner lining 4 mm, continuously welded, rising backwards in the last 2,500 mm

Floor panel 6 mm or rear panel in a length of approx. 2,000 mm - 10 mm thick

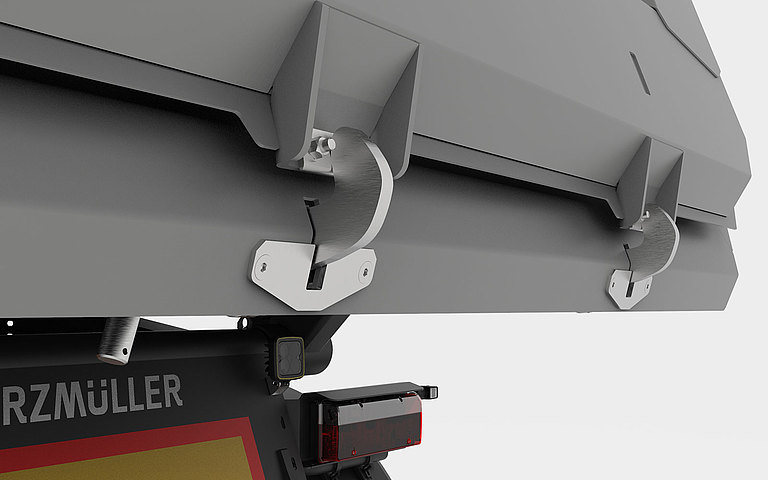

Aluminium rear wall = pendulum wall with low-level payload and automatic-mechanic 2-hook central lock;

1 hand lever;

Without excavator protection and ladder

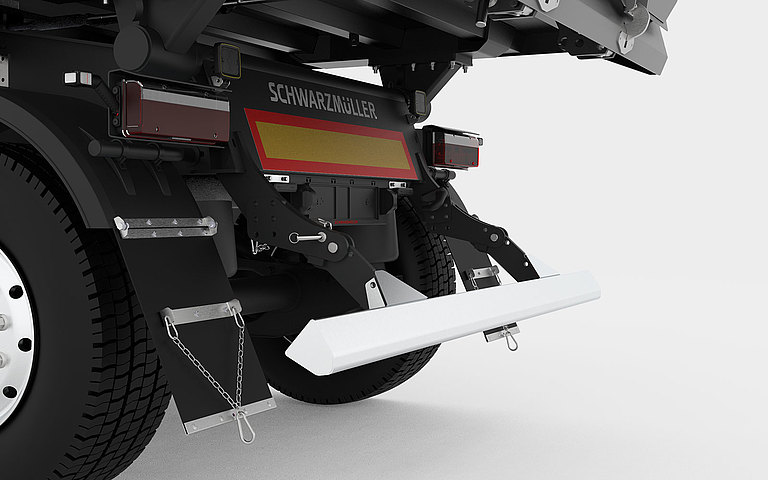

Fixed rear discharge chute (chassis clearance tipped approx. 600 mm)

Steel platform with aluminium safety grating, guard rail and foldable ladder on the left

Plastic roll tarp incl. aluminium tube and hand crank, without customs seal,

on the right with keder fastening on top box section,

zig-zag tie fastening in the front and back incl. control rod

1 removable transverse support and stop bracket on the right for roll tarp

Holder for rolled-up tarpaulin

Tarpaulin attached on the left with 3 mounting brackets and central front tensioner, without tension belts (quick lock on top box section)

24 V lighting system persuant to EC Directive 76/756/EEC

2 five-chamber LED tail lights

LED side marker lights

2 LED marker lights

2 LED contour lights

2 licence plate lamps

2 x 7-pin and 1 x 15-pin socket

Blasted with steel granulate, multilayer epoxy zinc phosphate primer and top coat with 2-component polyurethane top coat

Chassis = RAL ... (optional)

Painted body and rear wall = RAL ... (optional)

Plastic and hot-dip galvanised parts unpainted,

powder-coated attachments/mounting parts (black)

Reflecting contour marking strip on entire side length and reflecting circumferential contour marking at back (white on side and red at back by default) pursuant to ECE 48

Rear marking pursuant to ECE standard

Wheel chock(s) as per regulation

Noise dampers = rubber pads

Unpainted folding trapezoidal aluminium underride protection

Plastic single wheel mudguards with spray protection as per regulation

Side impact protection

Mount for brake and electrical connections under the standing platform in the front

Total train weight (adms.) 40 t

Total weight (techn.) 39 t

Axle assembly load (techn) 27 t

Fifth-wheel load (techn.) 12 t

Payload approx. 28 - 29 t

Tare weight approx. 5.2 t (+/- DIN tolerance)

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.