3-axle steel segment tipper semitrailer

- Stable and torsionally rigid chassis construction with additional torsion tubes

- Maximum stability thanks to automatic lowering device

- Hard chrome-plated, high-quality front tilt cylinder

- Specially canted Hardox body for maximum impact and wear protection

- Optimum load distribution thanks to slanted front wall

- Standing platform at front wall for operating roller tarpaulin

- Installation of axles from well-known manufacturers such as SAF or BPW

- OPTIONAL: Body sizes available for different load volumes

- OPTIONAL: lightweight segmental steel tipper with 4 mm floor thickness and 3 mm wall thickness - payload advantage approx. 300 kg

- OPTIONAL: External rear wall for higher load volume

- OPTIONAL: Special hinged rear wall for extra high opening with recessed mounting and automatic hydraulic operation

- OPTIONAL: Heavy-duty version for rock/stone transport with increased floor and wall thickness

- OPTIONAL: Roller cover - operated manually or via electric remote control

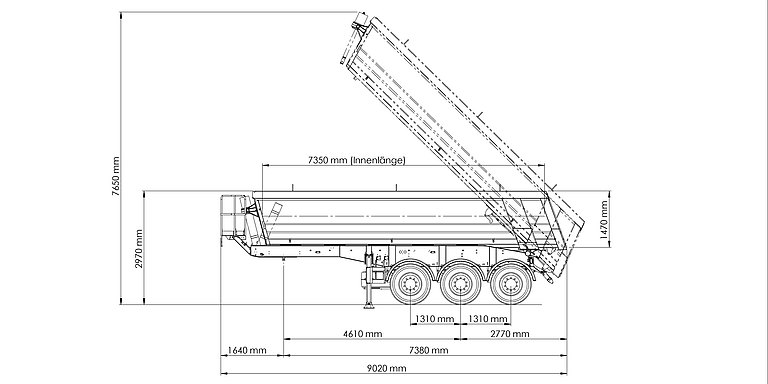

3-AXLE STEEL SEGMENT TIPPER SEMITRAILER

For rubble, excavated earth, etc. on building sites

Tipper body internal length: approx. 7,350 mm

Tipper body internal width: approx. 2,330 mm

Tipper body internal height: approx. 1,470 mm

= load volume: approx. 24 m³

Total width: 2,550 mm

Loading height, unladen: approx. 250 mm over fifth-wheel coupling

Naxtra welded steel frame construction in weight-optimised lightweight design

Replaceable 2" kingpin

Air suspension with autom. lowering device via inductive switch and lowering lock via rotary switch on semitrailer

air suspension unit with low-maintenance 430 mm disc brake axles, off-road version,

3 x 9 t rigid, wheelbase 2 x 1,310 mm

Autom. lifting front axle = raised or lowered according to weight, as well as forced lowering incl. integr. speed-restricted moving-off aid with button operation in cab (no button installation on our part)

Tyres :

6 x 385/65 R 22.5 160J, manufacturer as per factory specifications

6 steel wheel rims 11.75 x 22.5, 10-hole, 120 mm rim offset, silver

2 steel support legs, height-adjustable (only detachable when unladen)

Brake system according to EC Directive 71/320 or EC E R13

Two-line brake

Spring-loaded parking brake

EBS - electronic brake system

Wabco 2S2M = one axle sensed

RSS - stability program

Steel air tank

1 HP front press for rearward tipping, tipping angle approx. 45°

1 pipe system with screw coupling DN20

24 V lighting system according to EC Directive 76/756/E WG

2 seven-chamber tail lights

LED side marker lights

2 clearance lamps

2 contour lights

2 x 7-pin and 1 x 15-pin socket

Blasted with steel granulate, treated with zinc dust primer and spray painted with 2-component acrylic paints for commercial vehicles (standard RAL or truck colour)

Plastic and hot-dip galvanised parts unpainted,

powder-coated attachments/installation parts black

Reflective contour marking strips across entire length of sides and all-round contour marking at rear (white on sides and red at rear by default), according to ECE 48

Wheel chock(s) as per regulations

Noise dampers = rubber pads

Foldable aluminium trapezoidal underride protection, unpainted

Single wheel plastic mudguards with spray protection as per regulations

Gross train weight (perm.): 40 t

Gross weight (techn.): 39 t

Axle assembly load (techn.): 27 t

Fifth-wheel load (techn.): 12 t

Payload: approx. 27 t

Tare weight: approx. 6 t

Rear markings as per ECE standards

Complete steel body (incl. front and rear wall plus top belt) made of Hardox,

with reinforced top belt, floor thickness 5 mm, wall thickness 4 mm,

angled front and rear walls

Slanting front and rear walls, flush all over on top for roll cover

Rear wall = hinged wall with countersunk bearing and

automatic mechanical 2-hook central locking

Fixed discharge chute at rear = floor panels throughout (ground clearance when tipped: approx. 600 mm)

Steel standing platform with aluminium safety grate, with safety railing and steps,

on chassis frame

Plastic roll cover incl. aluminium tube, complete with hand crank, non-sealed,

Covers made as per factory specifications, cover colour subject to availability

Locking device for unrolled cover on right in direction of travel

Horizontal rope lashing cover bracket on the right side, zigzag lashing at front and back,

With 3 lashing straps on the left side incl. rubber pads, as well as

turnbuckles on the underside of the body

1 removable transverse support and stop bracket for roll cover on the right side

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.