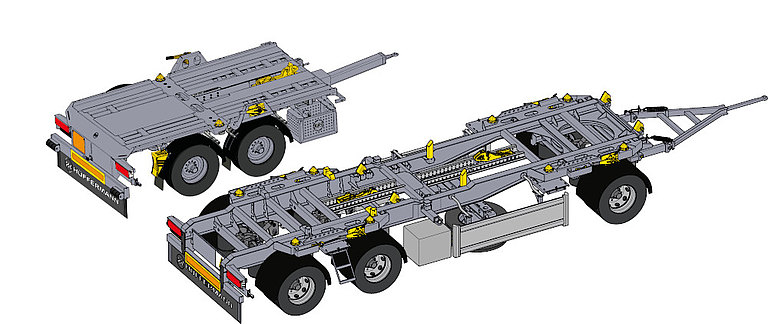

Vario carrier 2-axle turntable

- Robust, payload-optimised trailer for transporting skip containers in accordance with DIN 30720/30720-1

- "Made in Germany"

- Combined load securing crosswise and lengthwise as well as transverse lashing with one chain tensioner each

- Individual trailer configuration designed to meet your requirements

- OPTIONALS: Hüffermann elegance edition

- OPTIONALS: Version for one container with rear or front loading with lowering drawbar, version for 2 container to be loaded from both sides with lowering drawbar

- OPTIONALS: closed floor / equipment for transporting swap compactors

- OPTIONALS: Multi-Fix load securing without chains

- OPTIONALS: Safety-Fix time-saving load securing

VARIO CARRIER 2-AXLE TURNTABLE

Twin tyres HMA

Single tyres HMA

Various length versions

Front loading version

Versions for different international skip container standards

Total weight (techn./perm.): from 18 t – 20 t, depending on the national approval regulations

Additional or reduced weight depending on the equipment.

Skip container 5 m³ – 20 m³ (DIN 30720/30720-1)

Total lengths depending on the type design and drawbar selection

The frame consists of two parallel-running, specially designed longitudinal beams with I-profile, supported by optimised cross members that are welded by robots. The longitudinal beams serve as a support for the skip containers.

With flexible lashing points on the outer frame and corresponding push-locks, one or two containers of different sizes can be variably loaded at the payload centre of gravity.

We only use axles from renowned manufacturers. Air suspension chassis with disc brakes or drum brakes, including automatic lowering function

Tyres

8 tyres 235/75R 17.5 (10 t axles)

8 tyres 265/70R 19.5 (10 t axles)

4 tyres 385/55R 22.5 (9 t axles)

Other tyre sizes upon request.

Optional: Spare wheel, aluminium rims 19.5 / 22.5, tyre pressure monitoring and control systems, manual lifting/lowering function, axle load display.

- WABCO brake system with ABS and EBS

- Knorr brake system with ABS and RSP as an option

Optional:

- Brake pad wear display

- Rear area monitoring (Wabco)

Hella module lighting device with function lights with partially LED technology, including LED position light, LED outline marker lights at the rear and LED side marker lights, flashing.

Optional:

- LED work lights

- 2 additional LED reversing lights at the rear

- Three round LED tail lights, instead of the module lights

- Additional brake light on the centre panel

- Various warning and surrounding lights

- Independent "PS-Fix" parking light system

Paintwork in one RAL colour according to the customer’s wishes (except metallic colours), load securing elements in RAL 1003 signal yellow as standard.

Automatic blasting:

Before the paintwork, the trailer chassis are blasted in the automatic blasting machine specially designed for our trailer types, based on 12 consistently strong, automated and ring-shaped blast wheel turbines. Thanks to the special Hüffermann blasting abrasive, this results in a more homogeneous blasting pattern. Within the scope of the control process, additional blasting is performed manually, depending on the chassis design.

Priming: Application of an epoxy resin-based primer without electrostatics. Also for long-term and resilient corrosion protection.

Top coat: The 2-component top coat with a high solid content is individually applied in the desired colour (RAL) with the electrostatic method. As a result, even the smallest cracks are covered with paint and the protection and look is preserved over the years.

Sealing: After the assembly and the final approval of the vehicle from Quality Assurance, the vehicle is preserved at material contact points and transitions. Preservation is accomplished with Dinitrol cavity wax.

Standard version without paintwork on the side collision protection, silver rims. Axles with black CDP coating. Add-on parts are galvanised.

Optional: Arc galvanising

Zinc wire is melted by an arc, atomised with compressed air and applied onto the freshly blasted surface of the chassis (without add-on parts). Together with the subsequent paintwork, this achieves corrosion protection with similar properties as hot-dip galvanising. Another advantage is the low heat input. This ensures that the structure of high-strength steels is not modified and large areas do not tend to warp.

Electrical arc galvanising offers a clear advantage in terms of the duration of protection, hardness, bonding strength, abrasion resistance, stone chipping resistance and edge protection.

Rear marking

- ECE sign

Optional: Waste, parking or ADR signs

- Wheel chocks (2)

Optional storage areas:

- Standard storage box 600 x 500 x 500 mm

- Stainless steel storage box

- Storage area for nets in different sizes

- Pallet storage compartments

Turntable with sealed ball race and V-drawbar with 40 mm drawbar eye. Optional: Centre pillar drawbar or drawbar with adjustable length, different drawbar eye versions. On front loading trailers, a drawbar lowering device with air bellows control via a pneumatic valve outside of the hazard area. Field-tested lever arrangement, plus generously dimensioned lifting bellows for lifting and lowering the drawbar with low supply pressure. Lowering without ground contact (of the drawbar).

Skip containers are secured with combined load securing crosswise and lengthwise as well as transverse lashing with one chain tensioner each. The slip protector in the travel direction is accomplished with pluggable wedges with an oscillating contact surface, that adapts to the container inclination.

Centring Fix

The patented Centring Fix pyramid ensures lateral securing of the skip. It is lifted by hand out of the gimbal-guided eccentric design bearing, turned to the desired 8-stage centring dimension and pulled back into the lock by spring force. Optimal loading at the centre of gravity, even with different container sizes and weights, is ensured.

OPTIONAL: Multi-Fix

The time-saving and chain-free load securing locks the skip container on the tilt bearing in accordance with DIN 30720/ 30720-1.

OPTIONAL: Safety-Fix

The time-saving safety system is based on ratchet tensioners fastened on both sides. After installing the chains, the driver uses them to pull the container up to the stops. Afterwards, the driver only needs to tension one chain on each vehicle side at a lashing angle of 35 to 60 degrees to secure the container in the direction of travel with a positive-locking fit.

Underride guard, galvanised, with horizontal rubber buffer

Side collision protection consisting of two horizontal anodised aluminium profiles with fastening brackets that are rigidly mounted

Can be optionally swivelled up with gas pressure absorbers or with closed design

Plastic single wheel mudguard with spray guard

Optional:

1 spare wheel holder

Hüffermann rubber apron

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.