Steel segment tipper body for 4A truck

- Weight-optimised, torsionally rigid subframe construction

- Specially canted Hardox body for maximum impact and wear protection

- Hard chrome-plated, high-quality front tilt cylinder

- Compatible with all truck makes

- OPTIONAL: Body sizes available for different load volumes

- OPTIONAL: External rear wall for higher load volume

- OPTIONAL: Special hinged rear wall for extra high opening with recessed mounting and automatic hydraulic operation

- OPTIONAL: Heavy-duty version for rock/stone transport with increased floor and wall thickness

- OPTIONAL: Standing platform at front wall for operating roller tarpaulin

- OPTIONAL: Roller cover - operated manually or via electric remote control

- OPTIONAL: Dosing unit for hinged rear wall with pull-out pipe stop

- OPTIONAL: Foldable aluminium underride protection

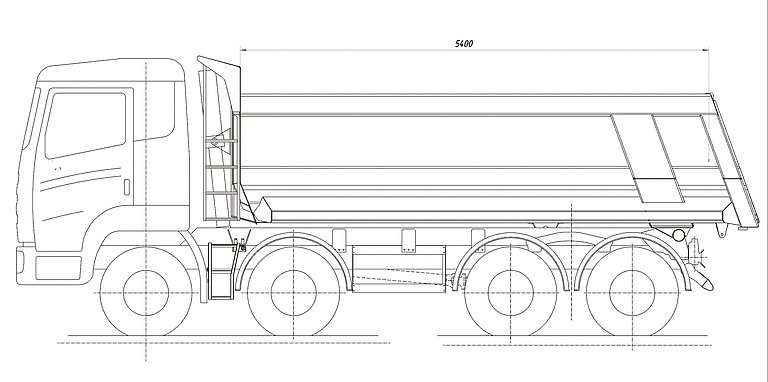

STEEL SEGMENT TIPPER BODY ON 4-AXLE TRUCK

For rubble, excavated earth, etc. on building sites

Body weight: approx. 3. 8 t

Internal length: approx. 5,400 mm (length = mean value with angled rear wall)

Internal width: approx. 2,330 mm

Internal height: approx. 1,470 mm

Load volume: approx. 17 m³

Total width: 2,550 mm

Body height, loading height etc. can only be checked and announced upon specification of the e xact truck data

Continuous side members with rearward tip shaft

Blasted with steel granulate, treated with zinc dust primer and spray painted

with 2-component acrylic paints for commercial vehicles (standard RAL or truck colour)

Plastic and hot-dip galvanised parts unpainted,

powder-coated attachments/installation parts black

Reflective contour marking strips across entire length of sides (continuing onto truck cab) and

all-round contour marking at rear (white on sides and red at rear by default), according to ECE 48

Rear markings as per ECE standards

Noise dampers = rubber pads

Bracket for wheel chock(s)

Mud flaps for rear mudguards

Shovel bracket on front wall

1 HP front press for rearward tipping, tipping angle approx. 50°

High-pressure hydraulic system with 80 l pump for direct flange mounting, 80 l oil reservoir with oil filling,

pneum. tip valve with overpressure protection and actuation in cab

Hardox steel body in semi-circular segmental construction with reinforced upper flange, Floor thickness 6 mm and wall thickness of 5 mm,

Vertical front wall with reinforcements and raised excavator protection

Angled rear wall = hinged with recessed mounting and autom. mech. locking

1 handle

Short discharge chute welded at rear

Continuous guard plate (apron) on sides

Fixed external ladder at front left and steps inside

(climbing aids must be present on truck)

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.