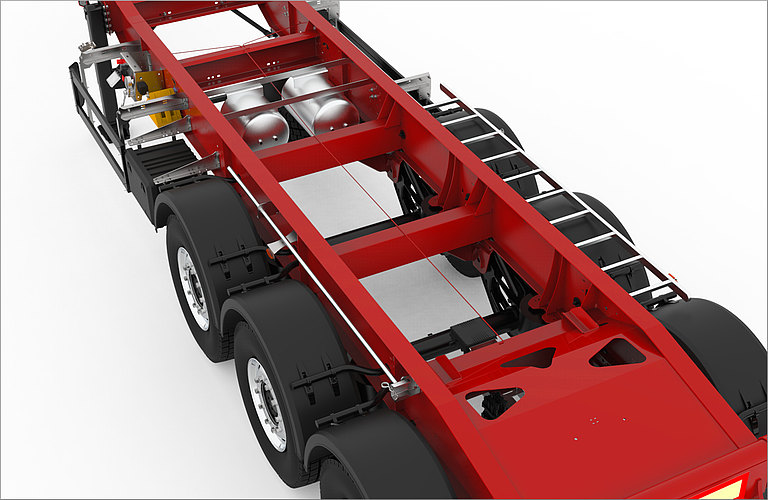

Full aluminium 3-axle large-scale tipper semitrailer

- Stable and torsionally rigid chassis design with extra torsion shafts

- Automatic lowering device for maximum stability

- High-quality front tilt cylinder with four-point support

- High-quality, hollow profile aluminium body for high resistance to impact and wear

- Standing platform at front wall for operating the roller tarpaulin

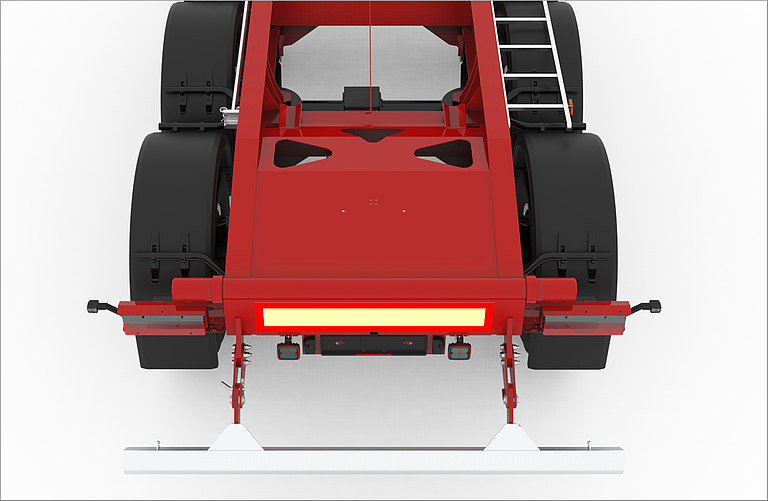

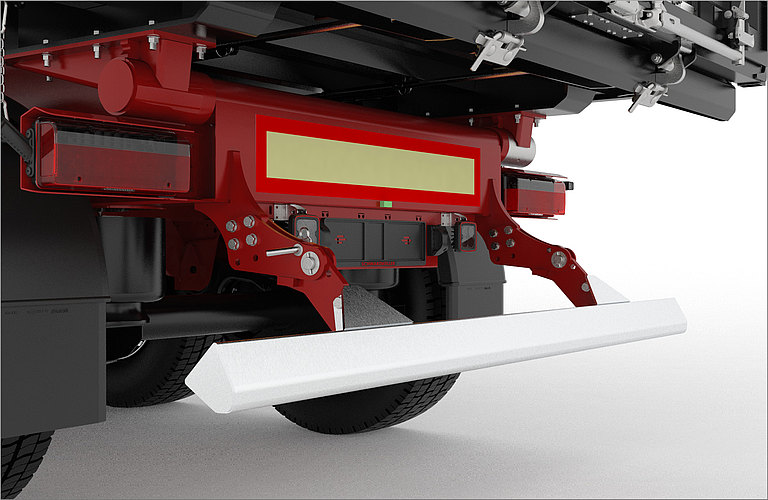

- Foldable, trapezoidal aluminium underride protection for practical filling of screw conveyors etc.

- Grain feeder in door leaf with dosing lever and water guard plate

- Axles from well-known manufacturers such as SAF or BPW

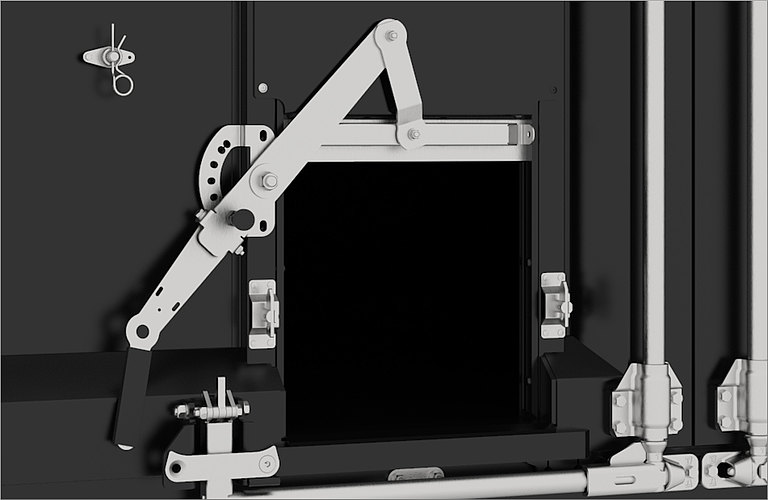

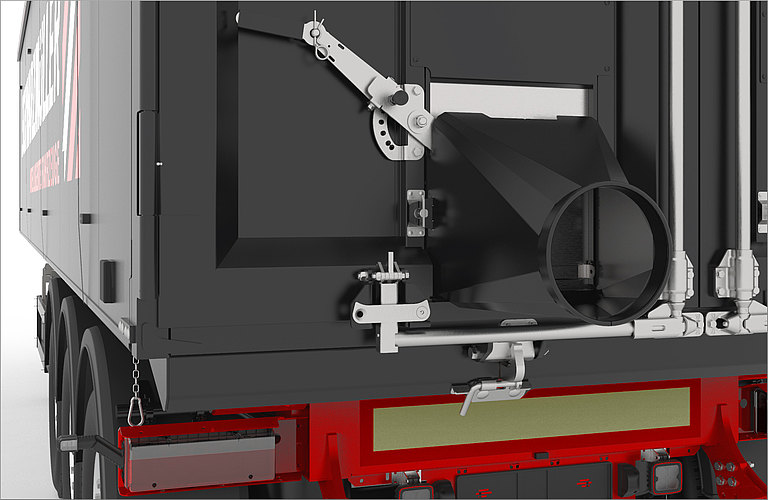

- Combined rear wall - fully opening, centrally divided double door with hinged frame and automatic locking mechanism

- Body sizes available for different cargo volumes

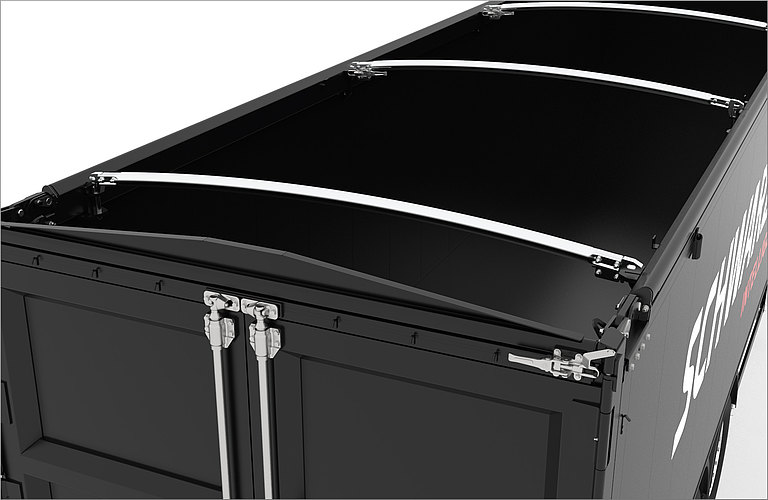

- Inclining cambered roof bars for extra stability and protection against unwanted water pooling

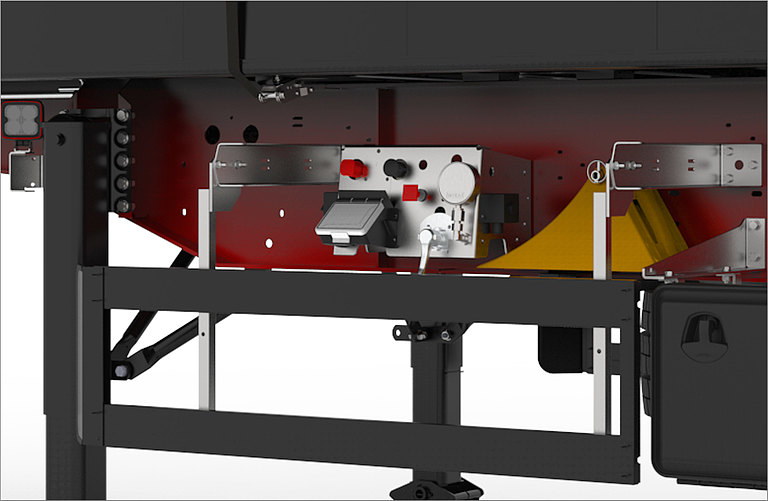

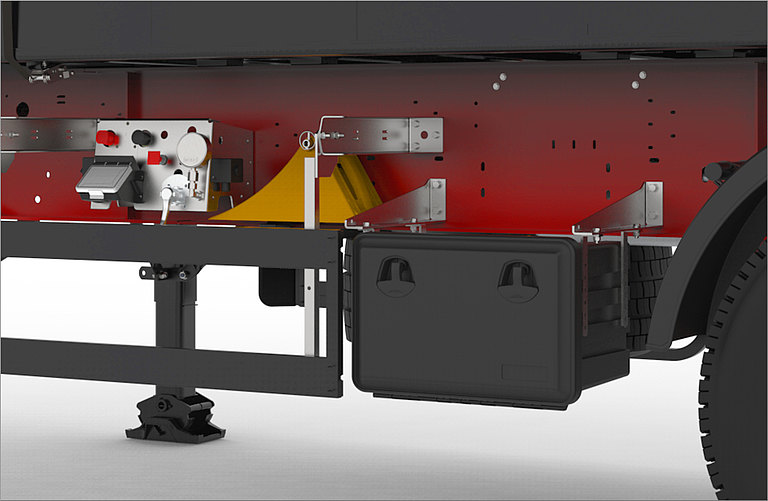

- OPTIONAL: Side-mounted control panel providing all control and monitoring elements

- OPTIONAL: Wear plates at rear of body for longer body life

- OPTIONAL: Removable discharge funnels (straight or conical) with optional dust bag

FULL ALUMINIUM 3-AXLE LAGE-SCALE TIPPER SEMITRAILER

for easily sliding bulk goods, pallet and grain transport

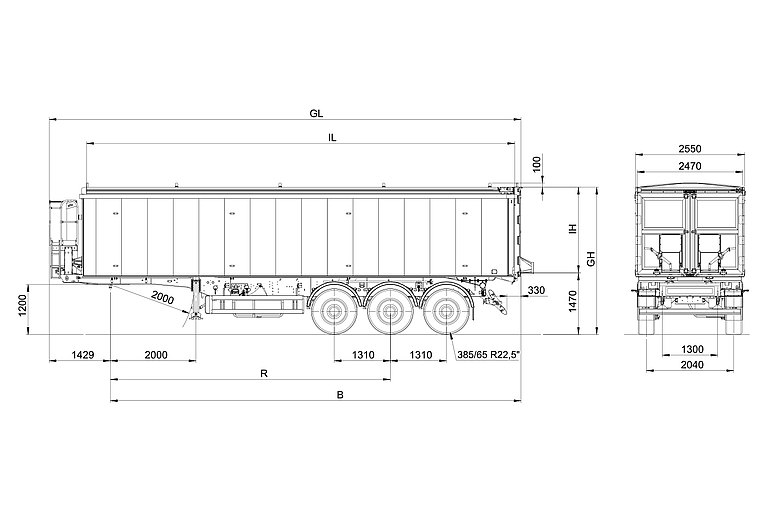

Internal length: approx. 10,000, 10,500, 11,500, 13,300 mm

Internal width: approx. 2,470mm

Internal height: approx. 2,000, 2,200, 2,300, 2,500 mm

Cargo volume: approx. 49, 52, 54, 57, 60, 62, 65, 76, 82 m³

Max. total width: 2,550 mm

Max. total height (unloaded): approx. 3,470 – 3,970 mm

Fifth wheel height: approx. 1,200 mm

Loading height (unloaded): approx. 1,470 mm

Welded aluminium frame design with rear tipping shaft

Replaceable 2” kingpin

Aluminium corner body in pallet design = smooth inside and outside, vertical front and rear walls, discharge chute not included

Reinforced front wall without excavator protection

Side and rear walls made from hollow profiles with upper frame on top

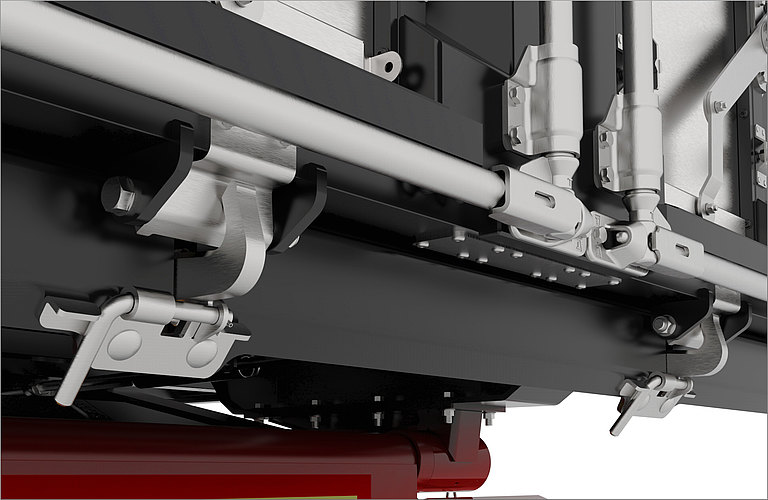

Crosspiece at back = pivoting door lock rod including actuation rod

Uniform fixed support across front wall and rear crosspiece

End-to-end floor panel with narrow cross ribs

(warping after welding may provoke minor corrugation)

Completely seal-welded inside of side walls

Combination rear wall = centrally divided double door with 1 external espagnolette and door latch each plus extra double hinged frame including automatic locking mechanism and shutoff of sliding discharge gate

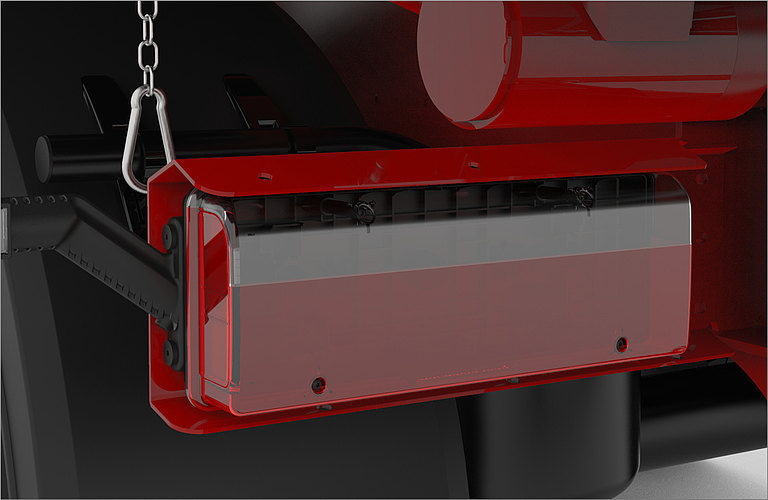

1 grain feeder (approx. 400/400 mm) per door leaf with side-mounted dosing lever and water guard plate

Primer and top coats spray painted with 2-component acrylic varnishes for commercial vehicles

Black plastic parts not painted

Powder-coated black attachments/mountings

Hot-dip galvanised parts not painted

Aluminium platform with aluminium safety grating, guard rail and ladder included

Aluminium side impact protection profiles

Spare wheel bracket not included

1 aluminium ladder, bracket included

Labelling, operating and safety instructions in German

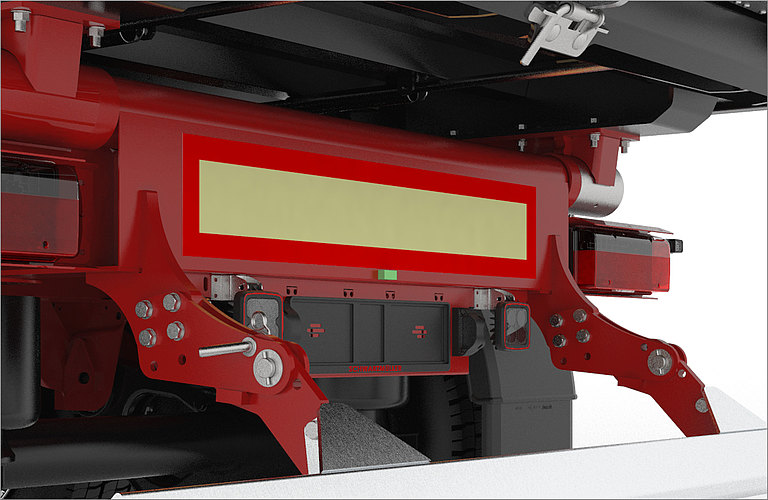

Licence plate frame

Rear marking pursuant to ECE

CE mark of conformity

Gross weight (techn.): 39 t

Axle assembly load (techn.): 27 t

Fifth-wheel load (techn.): 12 t

Tare weight: approx. 5,7 t or heavier (+/- DIN tolerance)

1 level gauge (to check horizontal position)

3 pairs of plastic single wheel mudguards with spray protection as per regulations

Unpainted folding trapezoidal aluminium underride protection, aluminium latch included

2 wheel chock and holders as per regulations

Removable grain feeder discharge funnel, dust bag not included, mounted on chassis

Noise dampers = rubber pads

Aluminium support jack, 2 x 12 t, mechanically operated on the right, including pivot foot, further options to choose from

SAF Intradisc axles with disc brakes

Axle load: 9 t/axle, on-road models

Wheelbase: 1,310 + 1,310 mm

Automatically lifting front axle

6x 385/65 R 22.5, 160K tyre

6x 11.75 x 22.5 steel or aluminium rim

Spare tyre not included

Brake system pursuant to EC Directives 71/320 and/or ECE R13

Two-line compressed air brake system

Wabco brake system

EBS system plus RSS stability programme

Spring-loaded parking brake on 2 axles

Steel or aluminium air tank

2 separate yellow/red brake/air line couplings

Electronic air suspension with automatic lowering device operated by inductive switch and lowering lock operated by rotary switch on semitrailer

Hose or cable connections to semitrailer tractor not included

1-tube system with screw coupling

Hydraulic hose connection to semitrailer truck not included

High-pressure front cylinder for backward tipping, tipping angle: approx. 45 degrees

Plastic roller tarpaulin incl. aluminium slat and hand crank on right in travelling direction

Horizontal tarpaulin bracket rope fastening, 3 stop brackets plus holder for rolled-up tarpaulin; tarpaulin hook at front and back with zig-zag tie fastening

3 central removable and swivelling rube crosspieces = also serve as tarpaulin support, approx. 100 mm inclination

Tarpaulin attached on left in travelling direction by means of 4 tension belts (rubber pads included) and turnbuckles on tipper body’s underside

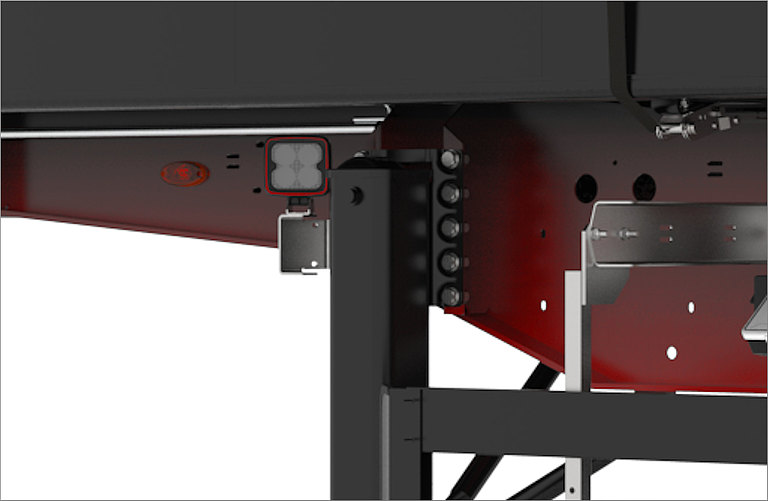

24 V lighting system pursuant to EC Directive 76/756/EEC

2 five-chamber LED tail lights

2 LED front marker lights

2 LED rear contour lights

LED side marker lights

2 licence plate lights

2 7-pin sockets (1x DIN ISO 3731, 1x DIN ISO 1185) and 1 15-pin socket (DIN ISO 12098)

Power connection(s) to semitrailer tractor not included

White reflecting contour marking strips on entire bottom length of side walls plus 2 top corners pursuant to ECE 48

Red reflecting circumferential contour marking strip at back pursuant to ECE 48

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.