3-axle large-scale sliding tarpaulin platform semitrailer

- Low corrosion, high-quality aluminium body components, tested according to EN 12642

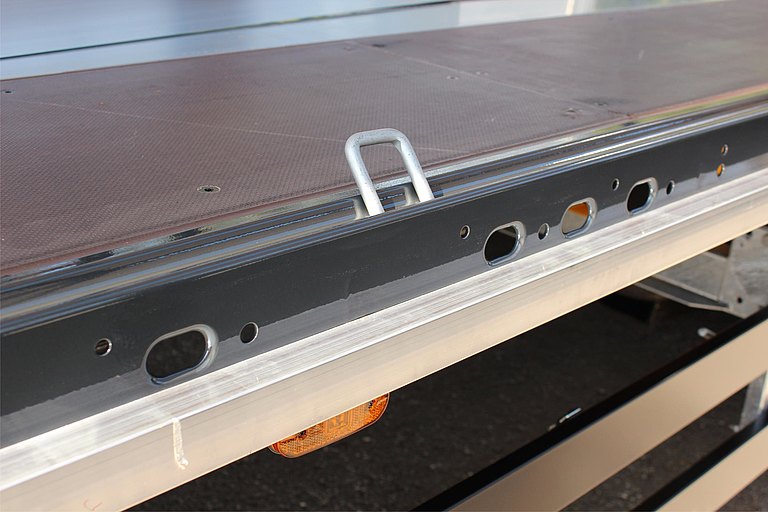

- Perforated external frame (starting approx. 3,000 mm from front wall) with approx. 100 mm hole spacing, 40/25 mm slot according to DIN EN 12640 and 23 pairs of recessed 2,5 t lashing points

- Aluminium tarpaulin mounting strips on both sides of external frame

- Reinforced aluminium hollow profile front wall with integrated equipment bracket

- Bolted portal at rear with aluminium corner posts and fully opening double door in profile design

- Resin-coated plywood floor, 27 mm, flush with external frame (floor load capacity: 7 t stacker axle load acc. to CSC)

- Manually operated hydraulic lifting roof, 400 mm elevation for rapid loading and unloading

- Installation of axles from well-known manufacturers such as SAF or BPW

- OPTIONAL: Internal height extendible by 60 mm via lifting roof, thus providing greater load height

- OPTIONAL: Version with sliding tarpaulin + side walls

- OPTIONAL: RULASI = post-based load securing system with various rack positions

- OPTIONAL: Twin-level loading system CTD III for 11 x 3 EURO pallets, load capacity: 400 kg/pallet

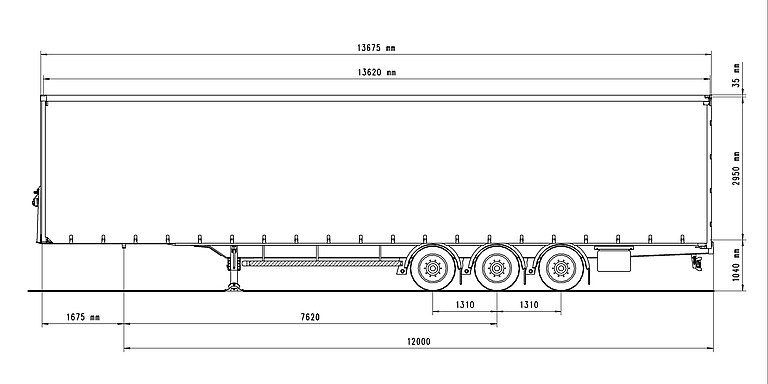

3-AXLE LARGE-SCALE SLIDING TARPAULIN PLATFORM SEMITRAILER RH80

Gross train weight (perm.): 40 t

Gross weight (techn.): 39 t

Axle assembly load (techn.): 27 t

Fifth-wheel load (techn.): 12 t

Tare weight: approx. 6. 3 t

Internal platform length: approx. 13,620 mm

Internal platform width: approx. 2,480 mm

Total width: 2,550 mm

Load space internal height: approx. 2,945 mm

Lateral loading height below guide rail: approx. 2,790 mm

Internal/total height adjustable by 60 mm = 2nd load space height approx. 3,005 mm

Internal width between guide rails: approx. 2,490 mm

Portal loading height: approx. 2,760 mm

Portal loading width: approx. 2,480 mm

Loading height: approx. 80 mm over fifth-wheel height

Welded steel frame construction in special low design

Frame for unladen fifth-wheel height of 960 - 1,050 mm

with air-sprung STT

Replaceable 2" kingpin (EC installation dimension, width across corners: 2,040 mm)

Perforated external frame (starting approx. 3,000 mm from front wall) holes approx. 100 mm apart , 40/25 mm slot according to DIN EN 12640 and 23 pairs of recessed 2.5 t lashing points

Air suspension with lifting and lowering device, approx. 250 mm

(approx. +180/-70 mm)

Automatic adjustment of driving level from 15 km/h

air suspension unit with low-maintenance 370 mm disc brake axles

3 x 9 t rigid, wheelbase 2 x 1,310 mm

Tyres :

6 x 435/50 R 19.5 160J, Goodyear Fuelmax T

6 steel wheel rims 14.00 x 19.5, 10-hole, with rim offset, silver

Mechan. 2 x 12 t support jacks, single-sided operation and thrust compensation, manufacturer as per factory specifications

Brake system according to EC Directive 71/320 or EC E R13

Two-line brake

EBS - electronic brake system

Wabco 2S2M = one axle sensed

RSS - stability program

Spring-loaded parking brake on 2 axles

Steel air tank

Resin-coated plywood floor, 27 mm, flush with external frame

2 steel top-hat rails above the longitudinal beams

(floor load capacity: 7 t stacker axle load acc. to CSC)

24 V lighting system according to EC Directive 76/756/E WG

2 seven-chamber tail lights in underride protection

LED side marker lights

2 clearance lamps

2 contour lights on underride protection

2 x 7-pin and 1 x 15-pin socket

Blasted with steel granulate, treated with zinc dust primer and spray painted with 2-component acrylic paints for commercial vehicles (standard RAL or truck colour)

Plastic and hot-dip galvanised parts unpainted,

powder-coated attachments/installation parts black

Reflective contour marking strips across entire length of sides and all-round contour marking at rear (white on sides and red at rear by default), according to ECE 48

Rear markings as per ECE standards (horizontal on rear doors/rear wall)

Rear crash guard with portal post protection and lower post reinforcement

Wheel chock(s) as per regulations

1 x retractable step unit at rear right

Single wheel plastic mudguards with spray protection as per regulations

Aluminium tarpaulin mounting strips bolted on both sides of external frame

Aluminium underride protection, coated white

Side impact protection made from aluminium profiles as per regulations, coated black

1 spare wheel bracket for 1 spare wheel (on right after axle)

1 plastic toolbox, lockable, unpainted , on left after axle

Fixed aluminium hollow profile front wall, 2,550 mm, with 2 centre supports,

2 lashing rings inside for load securing

Closed with tarpaulin over front wall, in same colour as side tarpaulin

Front wall reinforced inside with galvanised steel plate, approx. 650 mm high

Plastic sliding tarpaulins on both sides with load certification according to Code XL; welded horizontal and vertical strap reinforcements incl. lower fastening straps with flat hooks and stainless steel turnbuckles as well as front and rear bolt locks, openable on all 4 corners, with ratchet tensioner at rear,

t arpaulin sealed against external frame ,

tarpaulin manufacturer as per factory specifications, tarpaulin colour according to availability

Aramid-reinforced plastic roof tarpaulin, translucent

Bolted portal at rear with aluminium corner posts, upper crossbeam with forward-sliding cover, incl. fully opening double door in profile design covering entire load space height, each leaf equipped with 2 internal espagnolettes

2 fixed aluminium corner posts at front, bolted, protruding from sides

3 centre posts on left in direction of travel, movable across entire length, for lifting roof incl. Expander lifting aid

3 centre posts on right in direction of travel, movable across entire length, for lifting roof incl. Expander lifting aid

3 additional post pockets on both sides

4 rows of slat pockets, 1st pocket row at bottom 460 mm, spacing approx. 160/600/600 mm, with 4 rows of aluminium pointed slats 100/25 mm

Manually operated hydraulic lifting roof, 400 mm elevation, with lever operation on corner posts, for loading and unloading (portal doors must be opened)

Versus sliding cover with plastic brackets, forward-sliding with automatic elevation = pushed together in loading area, with vertical and horizontal guide rollers = smooth operation

Aluminium pallet guide rail profile on both sides for sliding tarpaulins and posts, design height 195 mm

Control rod for sliding tarpaulin (bracket on interior side protection)

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.