Sliding tarpaulin platform body for 2A truck

- Low corrosion, high-quality aluminium body components, tested according to EN 12642 Code XL

- Welded subframe structure with attached cross members (normal model)

- Welded subframe structure with inserted cross members (low-profile model)

- Bolted portal at rear with aluminium corner posts and fully opening double door in profile design

- External frame with recessed 2.5 t lashing points

- Double floor consisting of subfloor with integrated steel omega profiles beneath resin-coated wear floor (stacker axle load: 5,460 kg)

- Additional protection in the form of aluminium combination bumper strip, bolted on both sides, with integrated tarpaulin mounting and pole fixation

- OPTIONAL: Special tow attachment for low-clearance, central axle trailers

- OPTIONAL: Version with sliding tarpaulin + side walls

- OPTIONAL: Vertical liftgate with upper extending flap, for distribution transport

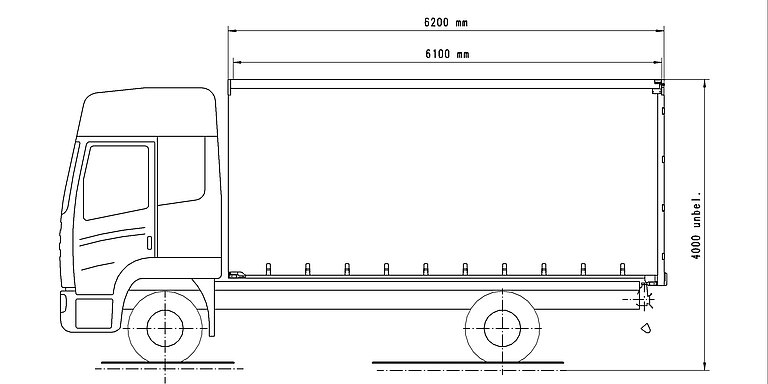

SLIDING TARPAULIN PLATFORM BODY ON 2-AXLE TRUCK

Body weight: approx. 1.7 t

Internal platform length: approx. 6,100 mm

Internal platform width: approx. 2,480 mm

Total width: 2,550 mm

Total height, unladen, adapted to approx. 4,000 mm

Internal width between guide rails: approx. 2,430 mm

Portal loading width: approx. 2,480 mm

Load space internal height, body height, loading height, total height etc. can only be checked

and announced upon specification of the exact truck data

Welded steel frame construction with attached/inserted cross members

11 pairs of recessed 2.5 t lashing points according to UVV

Spruce subfloor, 30 mm, lengthwise

Galvanised steel omega profiles in subfloor

Secondary floor made from resin-coated birch plywood, 9 mm, flush with external frame

(floor load capacity: 5,460 kg stacker axle load acc. to CSC)

Fixed aluminium hollow profile front wall, 2,400 mm, with 2 centre supports,

2 lashing rings inside for load securing

Closed with tarpaulin over front wall, in same colour as side tarpaulin

Front wall reinforced inside with 3/5 mm aluminium chequer plate, approx. 650 mm high

Plastic sliding tarpaulins on both sides with load certification according to Code XL; welded horizontal and vertical strap reinforcements incl. turnbuckles as well as front and rear bolt locks, openable on all 4 corners, with ratchet tensioner at front and rear,

tarpaulin manufacturer as per factory specifications, tarpaulin colour according to availability

Plastic tarpaulin roof, translucent = white

Bolted portal at rear with aluminium corner posts, upper crossbeam with forward-sliding Edscha cover, incl. fully opening double door in tubular design covering entire load space height, each leaf equipped with 2 internal espagnolettes

2 fixed aluminium corner posts at front, bolted, protruding approx. 95 mm from sides

1 centre post on left in direction of travel, movable across entire length

1 centre post on right in direction of travel, movable across entire length

4 rows of slat pockets, 1st pocket row at bottom 460 mm,

spacing approx. 160/450/450 mm, with 4 rows of aluminium slats 100/25 mm

Edscha sliding cover frame with plastic brackets, forward-sliding with automatic elevation, limited backward movement (opened from above) = pushed together in loading area, with vertical and horizontal guide rollers = smooth operation

Aluminium guide rail profile on both sides for sliding tarpaulins and posts,

design height 125 mm, or approx. 140 mm with plastic sealing lip bent upwards

Blasted with steel granulate, treated with zinc dust primer and spray painted

2-component acrylic paints for commercial vehicles (standard RAL or truck colour)

Plastic and hot-dip galvanised parts unpainted,

powder-coated attachments/installation parts black

Reflective contour marking strips across entire length of sides (continuing onto truck cab) and all-round contour marking at rear

(white on sides and red at rear by default), according to ECE 48

Rear markings as per ECE standards

Rear crash guard with portal post protection and lower post reinforcement

Bracket for wheel chock(s)

1 x retractable step unit at rear right

Plastic mudguards with spray protection as per regulations

Aluminium combination bumper strip, bolted on both sides, for tarpaulin mounting

and slat fixation

Side impact protection made from aluminium profiles as per regulations, coated black

1 plastic toolbox , lockable, unpainted

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.