4-axle low-loader trailer with offset platform

- Raised platform at the front incl. offset frame, tapered corners

- High point loading due to narrow cross member spacing

- Pull-out extensions, on both sides of drop deck and rear taper, incl. extension planks for transporting wide loads

- Excavator shovel recess between cross members at rear

- 8 pairs of recessed foldable 10 t lashing rings in floor (6 in drop deck and 2 on raised platform)

- 5 pairs of 3 t lashing bars at bottom of external frame

- 1 accessory compartment at front centre of raised platform, with folding lid

- Installation of axles from well-known manufacturers such as SAF or BPW

- OPTIONAL: Offset drawbar with pivoting eye 40 + 50 mm

- OPTIONAL: 2-part loading ramps with motor-hydraulic ramp actuators

- OPTIONAL: Ramps with hydraulic lateral movement, operated on semitrailer

- OPTIONAL: Wheel recesses for transporting special vehicles

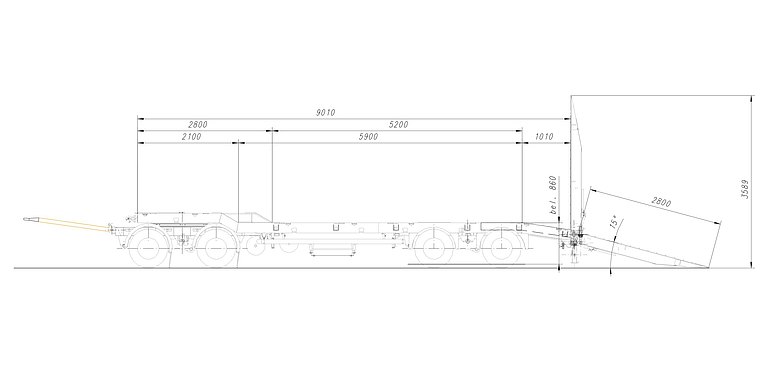

4-AXLE LOW LOADER TRAILER - TYPE TÜ

Gross weight (techn.): 40 t

Payload: approx. 32.1 t

Gross weight (perm.): 24 t

Tare weight: approx. 8 t

Approx. 2,800 mm = raised platform at front incl. frame offset

Approx. 5,200 or 5, 9 00 mm = drop-deck platform - flat load surface or external surfaces advanced

Approx. 1,000 mm = rear access slope

Total width: 2,550 mm or approx. 3,000 mm with extension

Loading height, laden: approx. 870 mm

Welded steel construction with flat front frame offset or body offset

and drive-on taper at rear

Excavator shovel recess = recess at rear between side members, approx. 1,850 mm long

6 pairs of mounting pockets for 100 x 50 mm tubular steel posts in external frame

(4 in the drop deck and 2 on raised platform)

5 pairs of 3 t lashing bars at bottom of external frame

8 pairs of recessed foldable 10 t lashing rings in floor ( 6 in drop deck and 2 on raised platform).

Reinforced, maintenance-free parabolic springs

Low-loader axles, each with 11 t axle load

S-cam brake 300/200 mm, autom. brake linkage adjuster

Dual-axle compensation at front and rear

Tyres :

16 x 2 4 5/7 0 R 17.5 14 3 J, manufacturer as per factory specifications

16 steel wheel rims 6.75 x 17.5, 10-hole, with rim offset, silver

Brake system according to EC Directive 71/320 or EC E R13

Two-line brake

EBS - electronic brake system

Wabco 4S3M = 1st and 3rd axles sensed

Spring-loaded parking brake on 3rd and 4th axles

Aluminium air tank

Spruce wood floor 50 mm, waterproofed, protruding approx. 5 - 10 mm beyond frame profiles or beyond steel stud plate cover over rear wheels

Pull-out extensions, on both sides of drop deck and rear taper,

extending parts hot-dip galvanised, incl. extension planks

(track width of construction machines/vehicles to be transported must not exceed external frame width of 2,550 mm)

2 pull-out/removable warning signs each at front and rear, extendible to 3,000 mm

2 foldable, 1-part loading ramps, approx. 2,800/750 mm

with hardwood flooring,

externally welded square ribs on ramps and

rear access slope

Ramp width manually adjustable , with rod (min. spacing approx. 300 mm up to max. total width of 2,8 1 0 mm)

lockable in driving position using chains with turnbuckle

2 autom. folding supports at rear

Lifting aid with coil spring

24 V lighting system according to EC Directive 76/756/E WG

2 five-chamber LED tail lights on ramps

LED side marker lights

1 clearance lamp for each front warning sign and

1 contour light on each rear warning sign

Fixed cable(s) with 2 x 7-pin or 1 x 15-pin connector

Bracket incl. revolving beacon on left ramp, with connecting cable and socket on end plate

Blasted with steel granulate, treated with zinc dust primer and spray painted 2-component acrylic paints for commercial vehicles (standard RAL or truck colour)

Plastic and hot-dip galvanised parts (extensions etc.) unpainted,

powder-coated attachments/installation parts and drawbar black

Reflective contour marking strips across entire length of sides and on the rear (white on sides and red at rear by default), according to ECE 48

Rear markings as per ECE standards

Wheel chock(s) as per regulations

Plastic mudguards or splashguards with spray protection as per regulations

Side impact protection

Spare wheel well for 1 spare wheel on right in direction of travel

1 accessory compartment at front centre of raised platform, with folding lid

Externally welded square ribs on ramps and rear access slope

Centre of gravity marking

Brackets for extension planks on frame on left in direction of travel

Fixed drawbar, 50 mm heavy-duty drawbar eye ,

with silent bushing

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.