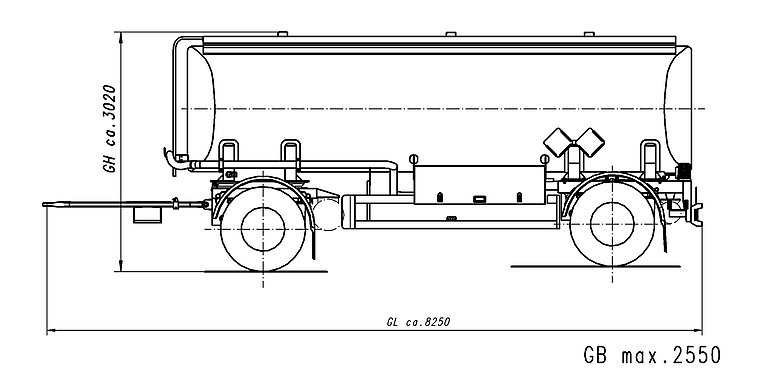

2-axle aluminium tank trailer without measuring system

- Sophisticated design with perfect functionality

- Optimum driving stability thanks to low centre of gravity

- Extremely light and flexible product discharge hoses (3" or 4")

- Box-like tank container with stable construction

- Optimum tank container storage incl. stainless steel chassis

- Installation of axles from well-known manufacturers such as SAF or BPW

- OPTIONAL: Choice of aluminium or stainless steel bumper

- OPTIONAL: High-set LED light holder with optional integration of reversing camera

- OPTIONAL: Facility for mounting spare wheel bracket

2-AXLE ALUMINIUM TANK TRAILER IN BOX BODY DESIGN

Without measuring system, for mineral oil transport

Vehicle designation acc. to 9.1.1.2 ADR: FL

Tank code acc. to 4.3.4.1 ADR: LGBF

Special provisions acc. to 6.8.4 ADR: TE 7, TE 19

For transporting petrol UN 1203,

diesel fuel and EL heating oil UN 1202

Turntable and rear axle assembly frame made of stainless steel

Low-maintenance ball bearing turntable

Drawbar, 40 mm drawbar eye , with rubber bearing and drawbar locking device

Spare wheel bracket

Aluminium discharge box

Aluminium bottom-loading box

Plastic mudguards with mud flaps and spray-suppression system

Aluminium underride protection

Axles

Low-maintenance air suspension axles and disc brakes

each with 9 t axle load

Suspension

Air suspension

Tyres

5 x 385/65 R 22.5 160J, manufacturer as per factory specifications

5 steel wheels, 11.75 x 22.5, 10-hole

120 mm rim offset

Brake system according to EC Directive 71/320 or ECE R13

Two-line brake

EBS-E = electronic brake system

WABCO 4S/3M = both axles sensed

RSS - stability program

Spring-loaded parking brake on 2nd axle

Aluminium air tank

Aluminium alloy and wall thickness as per ADR regulations

Box shape

Gross capacity: approx. 19,000 l

3 chambers, chamber division as per customer specification

Baffles, if techn. required

Overflow pan incl. outlet pipe(s)

Protection for dome fittings

Aluminium catwalk in pan with foldable railing

Aluminium ladder at front

Earthing pin on left and right

1 external cable drum with automatic winding mechanism

1 rotary plate (33/1203 or 30/1202) at rear

3 removable hazardous substance labels (flame symbol)

3 removable hazardous substance labels (environmentally hazardous substances)

Rear markings as per ECE standards

2 seven-chamber tail lights in underride protection

LED side marker lights

2 clearance lamps at front

2 contour lights on underride protection

15-pin socket

Priming and spray painting with 2-component acrylic paint for commercial vehicles (standard RAL or truck colour)

Chassis with attachments and transport containers unicoloured as per colour specifications

Plastic components unpainted

Powder-coated attachments/installation parts black

Contour markings

Continuous reflective stripe on left and right, white, in tank length

All-round at rear, segmented, red

Acceptance as per ADR

Tank documentation

Type approval

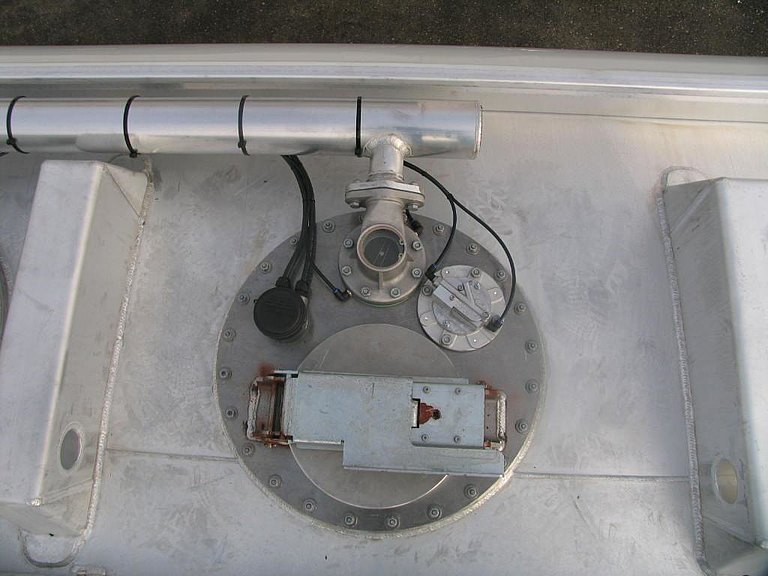

1 dome cover with rapid-fill lid

1 electro-optical top sensor

1 tip valve for ventilation

1 fan pot with flame arrester

1 pneum. bottom valve

Gross weight (techn.): 18 t

Tare weight, depending on equipment: approx. 3.45 t min.

Total width: 2,550 mm

Total height: approx. 3,020 mm

Total length: approx. 8,250 mm

Filling on left in direction of travel, output on right in direction of travel

One drain line DN 100 per bottom valve to distributor on left in direction of travel and connecting line to output on right in direction of travel

One API filling port per chamber incl. dummy cap on left in direction of travel

Trailer filling and drain line with 3" connecting hose

Gas return line connected to fan pots

Safety pressure relief/vacuum valve

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.