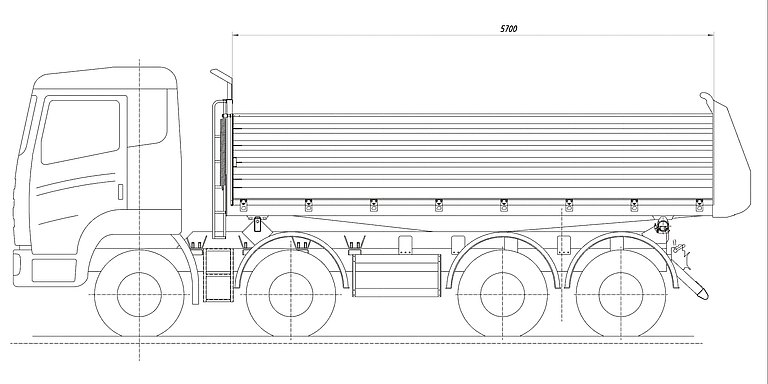

3-way tipper body for 4A truck - building site

- Insulated hollow chamber body for slow cooling, freezing and adhesion of load

- Tipper body construction using conical, trapezoidal profile side members in high-strength, lightweight design with small bottom panels for high dent resistance and shock absorption

- Torsionally rigid, weight-optimised subframe construction

- Hard chrome-plated, high-quality tilt cylinder

- OPTIONAL: Bordmatic (= hydraulically folding side wall) on left side

- OPTIONAL: Reinforced side walls with material-repellent membrane construction made from fine-grained special steel panels

- OPTIONAL: Electropneumatic side wall locking with switch operation in cab

- OPTIONAL: Aluminium flap on lateral central locking shaft

- OPTIONAL: Foldable lashing rings

- OPTIONAL: Foldable aluminium underride protection for road-finishing use

- OPTIONAL: Front and rear crane mounting with reinforced subframe

3-WAY TIPPER BODY ON 4-AXLE TRUCK - BUILDING SITE

For handling bulk materials such as sand, gravel, rubble, ground excavation etc. on building sites

Body weight: approx. 3.3 t

Internal length: approx. 5,700 mm

Internal width: approx. 2,420 mm

Load volume: approx. 15 m³

Total width: 2,550 mm

Body height, loading height etc. can only be checked and announced upon specification of the exact truck data

Blasted with steel granulate, treated with zinc dust primer and spray painted

2-component acrylic paints for commercial vehicles (standard RAL or truck colour)

Plastic and hot-dip galvanised parts unpainted,

powder-coated attachments black

Reflective contour marking strips across entire length of sides (continuing onto truck cab) and

all-round contour marking at rear (white on sides and red at rear by default), according to ECE 48

Rear markings as per ECE standards

Tipper body rubber centre support

Bracket for wheel chock(s)

Mud flaps for rear mudguards

Shovel and brush brackets

Rubber skirting on side walls on both sides

Fixed steel plate front wall, 4 mm, approx. 1,250 mm high

1-part reinforced aluminium hollow profile side walls, 60/4/3 mm, approx. 1,080 mm high,

foldable with extended swivel bolt locks and spring lifting aid,

hinged with pneumatic locking operated from cab

4 mm steel sheet rear wall, approx. 1,180 mm high, hinged with raised bearing and pneum. locking opened from cab

Fixed rear corner posts, raised, side-mounted, with discharge chute

Continuous side members with tilt cylinder bearings and outriggers

Body height above chassis: approx. 500 mm

Connector lock for tipper body with cross-over protection

27 t tilt cylinder for 3-way tipping, with safety rope,

80 l pump for direct flange mounting, 60 l oil reservoir with oil filling,

pneum. tip valve with overpressure protection and actuation in cab

Full-steel welded construction with fine-grained special steel floor panels, 6 mm

HARDOX HB450

(slight floor unevenness possible due to weld distortion)

Your Schwarzmüller contact persons

Always nearby. We are delighted to help.